How to Choose the Right Waveguide Pressure Window?

Waveguide Pressure Windows are critical components in many RF and microwave systems, especially when maintaining environmental isolation without compromising signal integrity. Selecting the right seal window is essential to ensure reliable performance across different applications — from radar and satellite communications to aerospace and EMC testing.

But with so many variables involved, how do you choose the most suitable waveguide seal window for your system?

Key Factors to Consider:

1.Operating Frequency

Waveguide dimensions and window design must align with your system’s frequency band. At AO Microwave, we offer custom pressure windows covering a wide frequency range — from low GHz bands up to 110 GHz.

2.Flange Type

The flange type determines the mechanical interface and compatibility with your system. Whether you require standard flanges (e.g., CPR, UDR, PDR) or customized flange patterns, we can tailor the solution accordingly.

3.Naterial Selection

Common materials include copper and lightweight aluminum, each offering distinct advantages in conductivity, weight, and cost. AO Microwave supports flexible material selection to meet both technical and budgetary needs.

4.Window Thickness and Dielectric Type

The dielectric window material (PTFE) and its thickness affect both transmission loss and sealing performance. We help clients balance RF transparency with mechanical durability through optimized design.

Why Choose AO Microwave?

At AO Microwave, we understand that no two systems are the same. That’s why we offer:

-

Fully customized Waveguide Pressure Windows based on your frequency, mechanical, and environmental requirements

-

Precision machining and quality assurance to ensure stable, low-loss performance

-

Fast design feedback and technical support, from concept to production

Whether you’re working on a satellite payload, a radar module, or an EMC test chamber, we can deliver the right seal window — built for your exact needs.

Contact AO Microwave (sales@aomicrowave) today to discuss your custom waveguide solution.

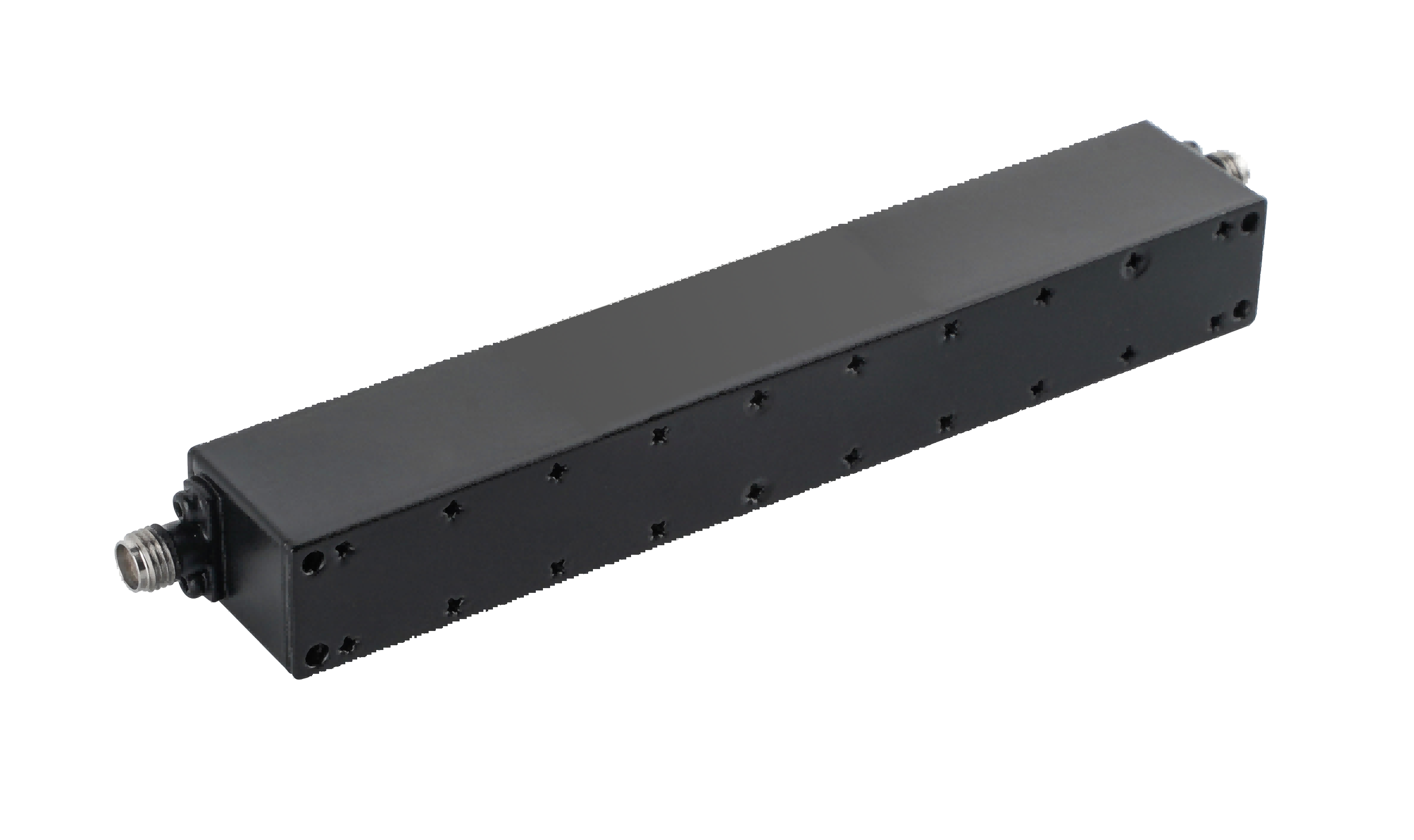

What Types of Coaxial Suspension Line Filters Are Available for RF and Microwave Systems?

What Types of Coaxial Suspension Line Filters Are Available for RF and Microwave Systems?

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

What's the Coaxial Suspension Line Filter?

What's the Coaxial Suspension Line Filter?

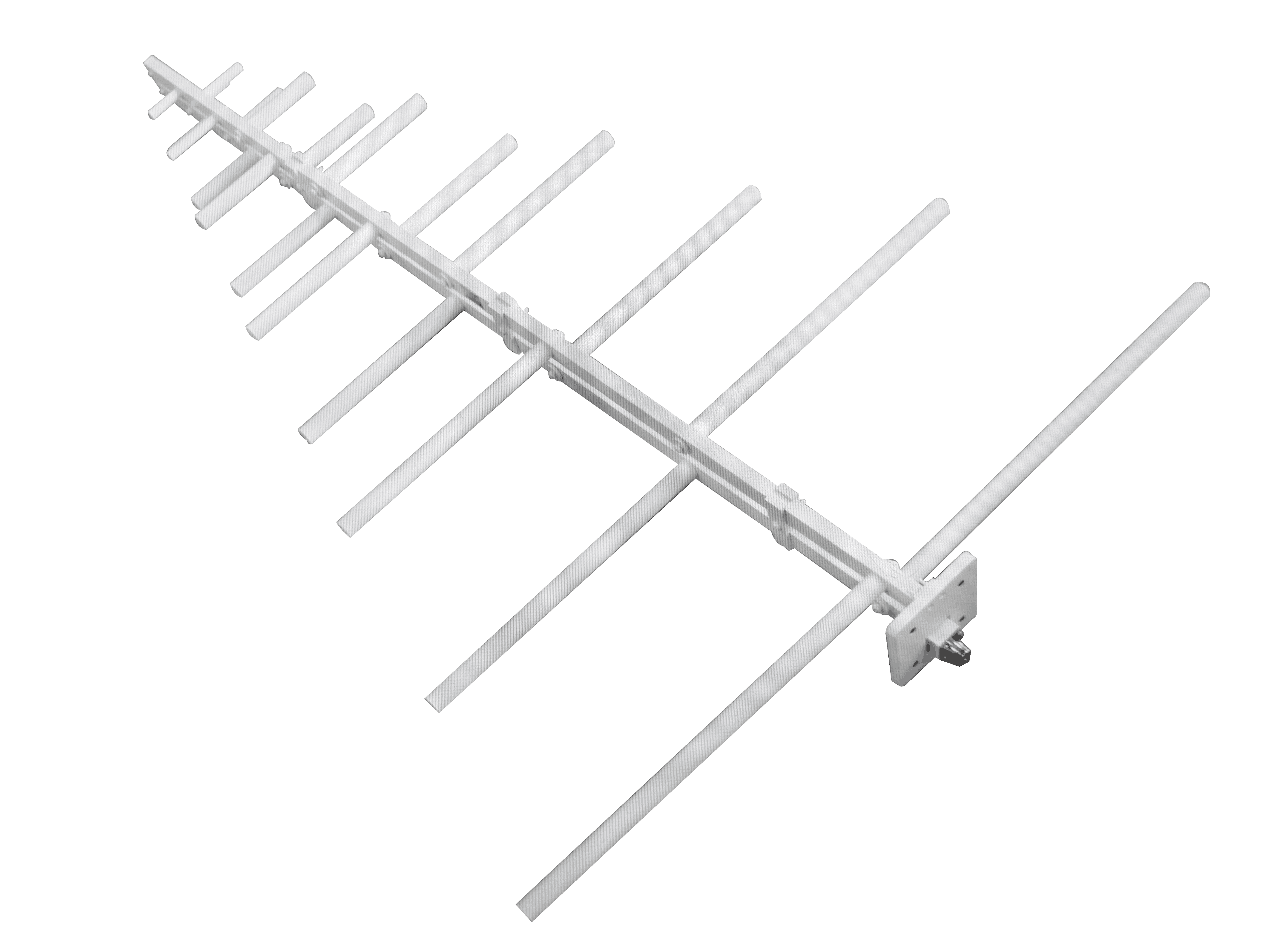

How to Choose a Log-Periodic Antenna for Long-Range Communication?

How to Choose a Log-Periodic Antenna for Long-Range Communication?