Why Do Cable Assemblies Need Armour?

In many RF and microwave applications, cable assemblies are exposed to harsh environments—ranging from mechanical stress and frequent handling to extreme temperatures and vibration. To ensure long-term reliability and performance, many critical systems require cables to be protected with armour. But why is armored protection so important?

1. Mechanical Protection

Armoured cables are shielded with an additional metallic layer—often stainless steel or flexible steel braiding—that safeguards the inner dielectric and conductor. This prevents crushing, bending damage, and accidental cuts during installation or operation.

2. Extended Durability in Harsh Environments

In aerospace, defense, and industrial applications, cables may be deployed outdoors, in vehicles, or near heavy machinery. Armour increases resistance to abrasion, wear, and impact, ensuring signal integrity even under demanding conditions.

3. Reduced Signal Loss Due to Stability

Cables without proper protection can suffer from micro-bending or deformation, which introduces VSWR variations and signal loss. Armouring minimizes these risks, preserving consistent electrical performance across the full frequency band.

4. Cost-Effective Reliability

While armoured cables may add initial cost, they greatly reduce the risk of system downtime and maintenance costs due to premature cable failure—making them a more economical choice over the system’s lifecycle.

At AO Microwave, we manufacture armoured RF and microwave cable assemblies designed for frequencies up to 110GHz. Our solutions are optimized for aerospace, radar, telecommunications, and EMC testing, where precision and durability are non-negotiable. We also provide custom armour options, from light protective braiding for lab use to heavy-duty stainless steel armoring for mission-critical field applications, including PTFE, PUR, PVC, Nylon and Stainless Steel etc types.

When reliability matters most, armoured cable assemblies are not optional—they’re essential.

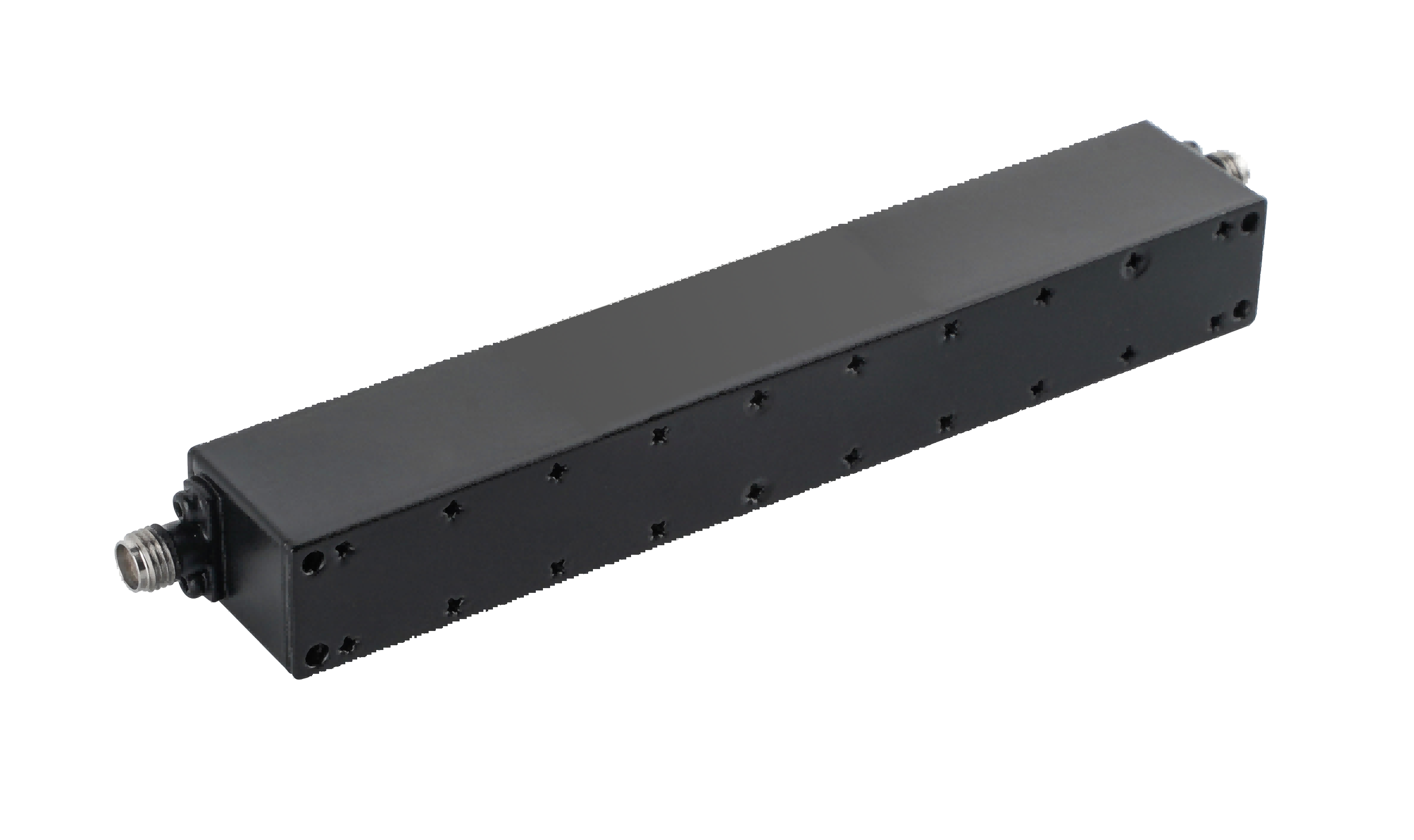

What Types of Coaxial Suspension Line Filters Are Available for RF and Microwave Systems?

What Types of Coaxial Suspension Line Filters Are Available for RF and Microwave Systems?

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

What's the Coaxial Suspension Line Filter?

What's the Coaxial Suspension Line Filter?

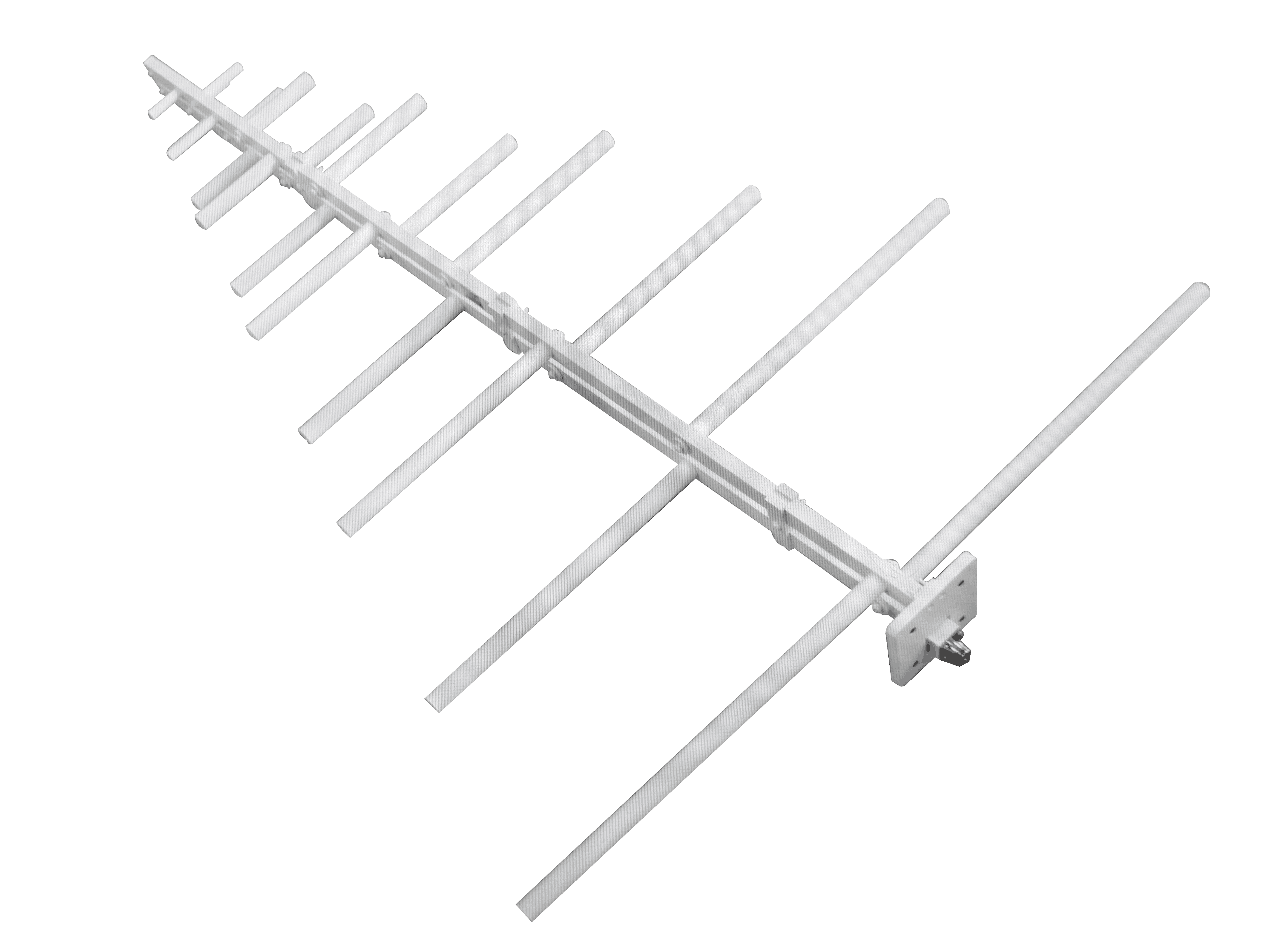

How to Choose a Log-Periodic Antenna for Long-Range Communication?

How to Choose a Log-Periodic Antenna for Long-Range Communication?